Accident and emergency preparedness

Accident preparedness

To ensure the reliable operation of equipment and production processes, prevent accidents, and mitigate their consequences for the environment and local communities, Nornickel applies a risk‑based approach to industrial safety management.

As the Company operates more than 300 hazardous facilities that use various hazardous substances in their processes, Nornickel’s facilities maintain ongoing emergency preparedness, including readiness to contain and respond to accidents.

Accident containment and response plans at hazardous facilities are approved by the heads (deputy heads) of production units that operate such facilities, and coordinated with the relevant heads (or deputy heads responsible for approving action plans) of professional emergency rescue services or units engaged in containment and response efforts.

These plans are reviewed and approved in accordance with established timeframes.

Plan validity periods

In 2024, Nornickel and Rostechnadzor took measures to enhance health and safety, including:

- continued implementation of the project to create a remote industrial safety compliance monitoring system at the hazard class 1 facility of the Kola site metals and mining enterprise (chlorine storage)

- deployment of the building and structure monitoring system (covering more than 1 thousand facilities connected to the information and diagnostic system)

- steps to improve the quality of industrial safety expertise and the organisation and delivery of routine repairs at hazardous facilities.

In addition, to prevent incidents similar to the one that occurred at CHPP‑3 in 2020, the Company is revamping fuel storage facilities at CHPP‑1, CHPP‑2, and CHPP‑3 in Norilsk.

For more details, please see the Climate Change section)

Emergency preparedness

In pursuing a targeted policy to mitigate the risks of major accidents at its production facilities, the Company acknowledges the potential for such accidents to escalate into emergencies that may endanger not only the lives and health of Nornickel employees but also of residents in the areas hosting the Company’s facilities. Emergencies may also result from hazardous natural phenomena characteristic of the Far North, such as extreme cold, snowstorms, and permafrost thawing.

The Group’s emergency preparedness system for critical and potentially hazardous facilities is implemented in accordance with Federal Law No. 68‑FZ, On Protection of the Population and Territories from Natural and Man‑Made Emergencies, dated 21 December 1994, as well as other laws and regulations of the Russian Federation and the Group’s internal regulations.

Emergency scenarios are modelled in an action plan for emergency prevention and response (the “plans”) to calculate the parameters of potential emergencies and provide detailed response procedures for personnel and emergency rescue units to protect the life and health of employees and the public, minimise environmental damage, and reduce material losses.

The plans are coordinated with the head of the local administration in the area where the Group operates, as well as with the heads of professional emergency rescue units responsible for providing coverage for the facilities. The plans are updated annually and fully revised every five years. The scenarios outlined in the plans are communicated to employees when they join the Company and during the annual emergency response briefing. The information provided covers the types of emergencies that may pose a threat at work or at home, along with guidance on how to stay safe in such situations. Regular emergency response drills are also conducted with employees and emergency rescue units to practice response procedures outlined in the plans.

Information exchange agreements have been signed with regional offices of the Ministry of the Russian Federation for Civil Defence, Emergencies, and Elimination of Consequences of Natural Disasters (EMERCOM), under which forecasts of potential emergencies are communicated for the areas where the Company’s facilities are located. The duty dispatch services at production units monitor the situation 24/7, issue emergency alerts to the public in the event of threats to life or health, and coordinate the rapid response of both professional and corporate emergency response teams.

To support emergency prevention and response measures, Group entities operating critical and potentially hazardous facilities have established financial and material reserves.

In 2023–2024, in accordance with updated national legislation, safety passports were developed for all critical and potentially hazardous facilities of the Group. Additional emergency response drills were conducted, resulting in emergency response preparedness certificates being issued.

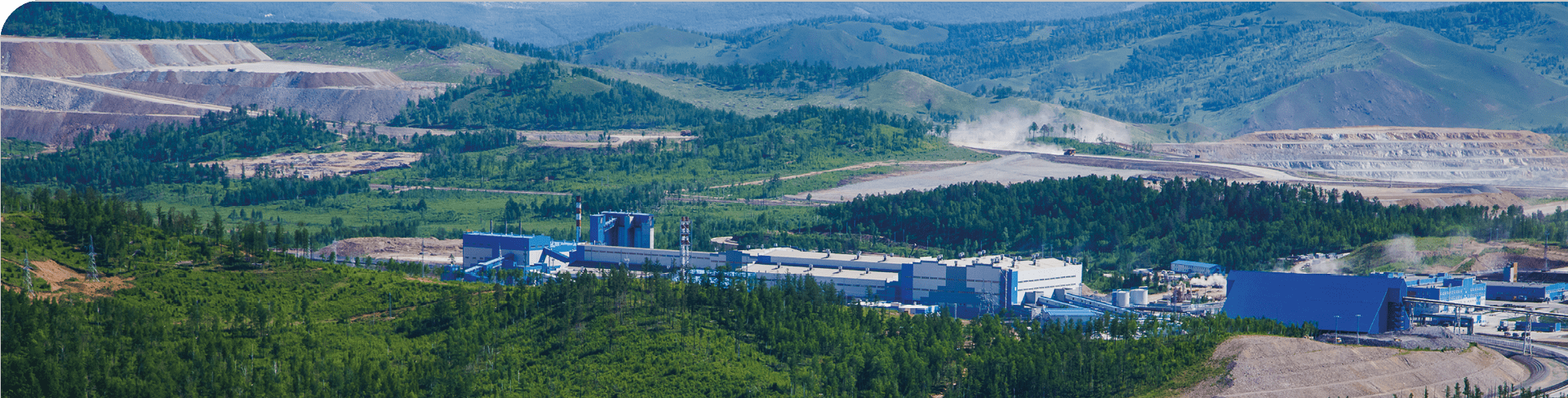

A complex of buildings has been constructed at the site of Nadezhda Metallurgical Plant to house the Company’s emergency response services. The complex includes:

- a fire station and training facility, designed to support 24/7 duty shifts for fire service personnel, accommodate firefighting equipment, and provide training for working at height

- a separate building accommodating the gas rescue service, including its personnel, vehicles, and equipment used in emergency and accident response at the Company’s facilities.

All Company enterprises are implementing programmes to equip their facilities with automated fire safety systems. In 2024, 141 facilities were fitted with advanced fire protection systems.